The Manufacturing Process of Golf Club Covers

JTS is a big golf head cover manufacturer. We supply premium quality golf headcover. We can custom logo and shape for you. Today, we talked about the Manufacturing Process of Golf Club Covers.

Golf isn’t only about how well you play, but also about showing your style and individuality. The headcover, which many people don’t pay much attention to, is really important for a golfer’s gear.

The right headcover

does two things: it keeps your clubs safe and shows off your style. It can start conversations and reveal a bit about who you are. This article explores eight unique golf headcovers, each offering distinct advantages and styles.

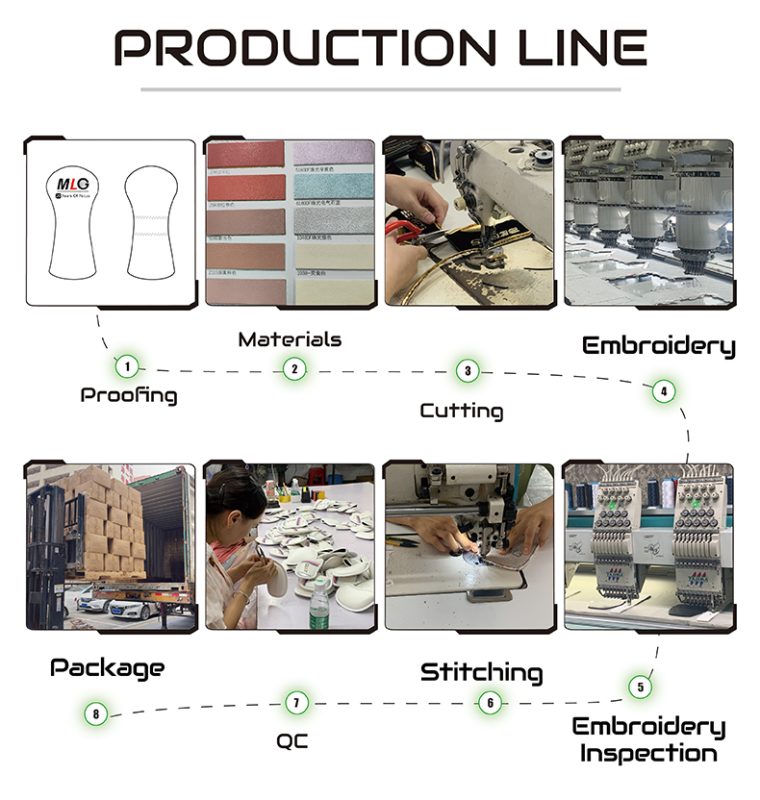

The production process of a golf club cover might seem straight forward, but it’s filled with precision and care to ensure top-notch quality and performance. Here’s a detailed look at each step involved in creating these protective sleeves:

- Design and Planning:

With the material selected, designers embark on creating visually appealing and functional designs. This stage involves deciding on colors, patterns, logos, and any unique elements that make the headcover stand out. For custom designs, golfers may provide their specifications or preferences.

- Material Selection:

– The second step in making a golf headcover is choosing the right materials. These can range from high-quality leather and synthetic leather to soft fleece, durable microfiber, and even recycled materials for an eco-friendly touch. Each material has its characteristics that affect durability, appearance, and texture.

2.1. Leather

– Natural Leather: This classic material provides a luxurious appearance and feels soft to the touch. It can develop a unique patina over time but requires more maintenance compared to synthetic options.

– Synthetic Leather: Also known as faux leather or leatherette, it offers a leather-like look and feel at a lower cost with less maintenance.

2.2. Fabrics

– Microfiber: A synthetic fabric that is soft, durable, and easy to clean. It provides a smooth, modern look and is commonly used in sports apparel and accessories.

– Fleece: This soft, plush material is warm to the touch and provides excellent protection. It is often used for winter head covers or for adding an extra layer of padding.

– Mesh: Offering breathability and often combined with other materials for added texture or design elements.

2.3. Rubber or Silicone

– Rubber: Sometimes used for the bottom grip of the head cover to ensure it stays in place during play or travel.

– Silicone: Can be incorporated into grip areas or as decorative elements, providing a non-slip surface.

- 4. Fur or Faux Fur

– Fur: Real or synthetic fur can provide an elegant and cozy appearance. Faux fur is a popular vegan-friendly alternative that mimics the look and feel of real fur.

- 5. Neoprene

– Neoprene (Wetsuit material): Offers water resistance and cushioning, making it ideal for protecting clubs in various weather conditions.

2.6. Recycled Materials

– Recycled Plastics: Some eco-conscious brands use recycled plastics or other sustainable materials to create environmentally friendly head covers.

2.7. Cotton and Polyester

– Cotton: Provides a classic, lightweight feel and can be easily decorated with prints or logos.

– Polyester: Durable and easy to maintain, often used for simple solid color designs or complex patterns.

2.8. Velvet

– Velvet: A rich, luxurious material that can add a touch of elegance to golf head covers.

- Pattern Making:

– Once the design is finalized, patterns are created to serve as blueprints for cutting the fabric. These patterns ensure that each piece of material is cut to the exact specifications needed for assembly.

- Cutting:

– Using the patterns, the chosen material is laid out and cut into pieces that will eventually be sewn together to form the club cover.

- Sewing and Assembly:

The cut pieces are then assembled, often involving stitching by hand or machine. Some headcovers may include additional features like zippers, Velcro strips, or magnetic closures for ease of use.

- Finishing Touches

Once assembled, the headcovers may undergo additional treatments or finishing touches. This could include painting, adding protective coatings, or applying final details like buttons or piping.

- Quality Control:

– Every club cover goes through a rigorous inspection process to identify any defects in workmanship or materials. Any issues found result in a return to the appropriate production step.

- 8. Packaging:

-The final step is packaging the headcovers securely for shipment to retailers or direct customers. Careful packaging helps prevent damage during transit.

Tips for Maintenance

To extend the life of your golf headcovers, follow these maintenance tips:

– Clean Regularly: Use a damp cloth and mild soap to wipe down your headcovers after use, removing dirt and grime.

– Avoid Sun Exposure: Keep your headcovers away from direct sunlight when not in use to prevent fading and material deterioration.

– Proper Storage: Store your headcovers in a cool, dry place, avoiding humidity which can lead to mold growth.

– Inspect Periodically: Regularly check for wear and tear, especially on seams and fastenings, and have them repaired promptly to avoid further damage.

By understanding the process behind making golf headcovers and following simple maintenance tips, you can enjoy these functional accessories for a longer time while also adding a personal touch to your golf gear.

Conclusion

In conclusion, JTS’s range of golf headcovers offers something for every golfer, blending style, functionality, and a touch of personal expression.

Incorporating one of these headcovers into your golf gear is a practical decision to safeguard your clubs and an opportunity to showcase your personality on the green.

As we’ve explored these diverse options, it’s clear that choosing the right headcover can elevate your golfing experience, adding both flair and function to every swing.

Remember, in golf, the details matter – and a great headcover is one of those details that truly counts.